Our skills

Pioneer and Expert in recharging solutions

Refill solutions have been part of our DNA for over three decades. Since 1992, we have led the way with the first fragrance fountains created for Thierry Mugler fragrances, marking the start of a revolution in the beauty industry.

Today, our innovations are used in the vast majority of fragrance refills on the market, consolidating our position as a world leader in this emerging market. As an ardent supporter of the circular economy, we use our expertise and creativity to create customised solutions that encourage the reuse of iconic bottles from major fragrance brands.

Injection specialist

Thanks to the heritage of Techniplast's two founders in a design office dedicated to the creation of plastic injection moulds, Techniplast has developed unique expertise in the design of customised moulds for the beauty packaging industry.

We meet the specific requirements of each project by combining responsiveness, precision and technical expertise in the design and manufacture of moulds. Working with a team of experts, we optimise the performance of our 20 injection moulding machines by integrating 100% electric machines that consume less energy than previous generations.

We take particular care to minimise our waste, which is then recycled and reused thanks to the skills of local partners.

Our expertise in injection moulding enables us to offer solutions that combine performance, efficiency and an aesthetic finish to meet the expectations of the luxury market.

Assembly specialist

Thanks to the knowledge and experience we've built up over the years, we can claim complete expertise in the assembly processes for our packaging solutions.

We coordinate every stage, from the initial design to the final integration of the machines in our workshops, to guarantee assemblies that perfectly meet the requirements of beauty brands.

Our dedicated teams study and develop customised assembly solutions, adapted to the most demanding production rates and aesthetic standards.

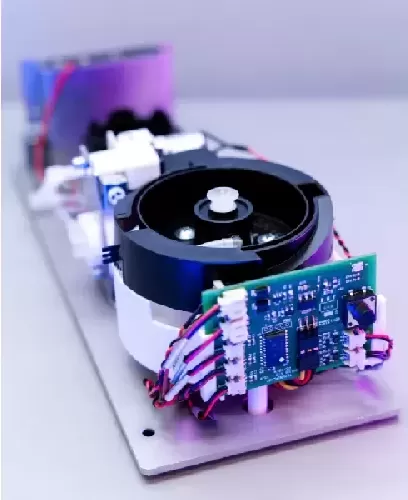

Manufacturers with electronics expertise

With our cutting-edge expertise in electronic development, we integrate advanced technology into our innovations to optimise perfume bottle filling principles.

Our team of specialists develops prototypes in our own laboratory, shaping the filling stations of the future.

Among other advantages, our advanced electronic systems enable precise, customizable filling. Integrated electronics also unlock innovative features, such as automatic dosing based on the size and shape of the perfume bottle.

By leveraging our expertise in electronics and digital technology, we open up endless possibilities for a truly modern and immersive customer experience.

French luxury expertise

Anchored in Normandy since the creation of TECHNIPLAST in 1988, our French expertise symbolises "Made in France" excellence in packaging.

By designing and manufacturing locally at our Louviers base, we comply with the strictest standards and meet the requirements of the most prestigious luxury brands. We have a perfect understanding of the specificities of their specifications and are able to adapt our processes with agility.

We take advantage of this proximity to the decision-making networks in the Paris region to offer our customers rapid, unfailing availability.

10 to 20

best-sellers per year

2 to 5

patented innovations per year

90%

of our innovations are sustainable